On July 8th, an international team led by Jing-Feng Li, professor from the School of Materials Science and Engineering at Tsinghua University, G. Jeffrey Snyder and Vinayak P. Dravid, professors at Northwestern University in U.S., published their collaborative work as an article in Advanced Materials. This research paper, entitled “Melt-centrifuged (Bi,Sb)2Te3: engineering microstructure towards high thermoelectric efficiency”, reported an unconventional melt-centrifugation technique that well tunes the microstructure and resultant thermoelectric transport properties of (Bi,Sb)2Te3. Using this new approach, a complex microstructure with large porosity and dense dislocations was obtained, leading to a great reduction in thermal conductivity due to both lack of conduction medium and phonon scattering.

Thermoelectrics which can convert heat into electricity in solid-state, and vice versa, are graining increasing attention in recent years. As one of the best thermoelectric materials at room temperature, (Bi,Sb)2Te3 alloys show are almost irreplaceable in the fields of solid-state electronic refrigeration and low-temperature waste heat power generation. How to further improve its thermoelectric performance has been receiving significant attention. Microstructure engineering (e.g. hierarchical architecture construction) is one of the most effective strategy to enhance the thermoelectric figure of merit (zT) by reducing lattice thermal conductivity.

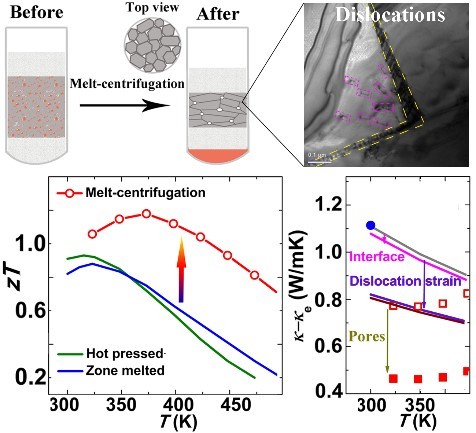

In this work, through a new process based on melt-centrifugation to squeeze out excess eutectic liquid, microstructure modulation is realized to manipulate the formation of dislocations and clean grain boundaries, resulting in a porous network with a platelet structure. In this way, phonon transport is strongly disrupted by a combination of porosity, pore surfaces/junctions, grain boundaries, and lattice dislocations. While the charge carriers remain relatively mobile across the liquid-fused grains. This porous material displays a zT value of 1.2, which is higher than fully dense conventional zone melted ingots and hot-pressed alloys. A segmented leg of melt-centrifuged Bi0.5Sb1.5Te3 and Bi0.3Sb1.7Te3 could produce a high device ZT exceeding 1.0 over the whole temperature range of 323–523 K and an efficiency up to 9%. The present work demonstrates a method for synthesizing high-efficiency porous thermoelectric materials through an unconventional melt-centrifugation technique.

Figure 1. Upper panels are schematic illustration of melt-centrifugation technique (left) and the resulted microstructure (right). Bottom panels are thermoelectric figure of merit (left) and the lattice thermal conductivity with a Debye model analysis presenting the contribution of interfaces, dislocation strain and porosity to the reduction (right).

Prof. Jing-Feng Li and Prof. Jeffrey Snyder are corresponding authors of this paper. Dr. Yu Pan, a PhD student from the School of Materials Science and Engineering (now a Postdoc at Max Planck Institute for Chemical Physics of Solids) is the first author of this paper. These studies received support from the Basic Science Center Project of NSFC under grant No.51788104 and the NSFC project No.11474176, as well as the Solid-State Solar-Thermal Energy Conversion Center (S3TEC), an Energy Frontier Research Center, funded by the U.S. Department of Energy, Office of Science, Basic Energy Sciences (DE-SC0001299 and DE-SC0014520). Y. P. would like to acknowledge the Chinese Scholarship Council (CSC) for her scholarship in Northwestern University.

Prof. Jing-Feng Li’s group focuses on the research of microstructure engineering, the mechanisms for the transport properties, along with the enhancement of thermoelectric performance of advanced thermoelectric materials. In the past few years, they have published a series of papers in Bi2Te3 material system, based on the point defects modulation, nanocomposite synthesis, microscale texturing and etc. (e.g. AFM2013、JMCC2015、NPG Asia Mater 2016、Adv Sci 2017).

Links to the publication: https://onlinelibrary.wiley.com/doi/abs/10.1002/adma.201802016